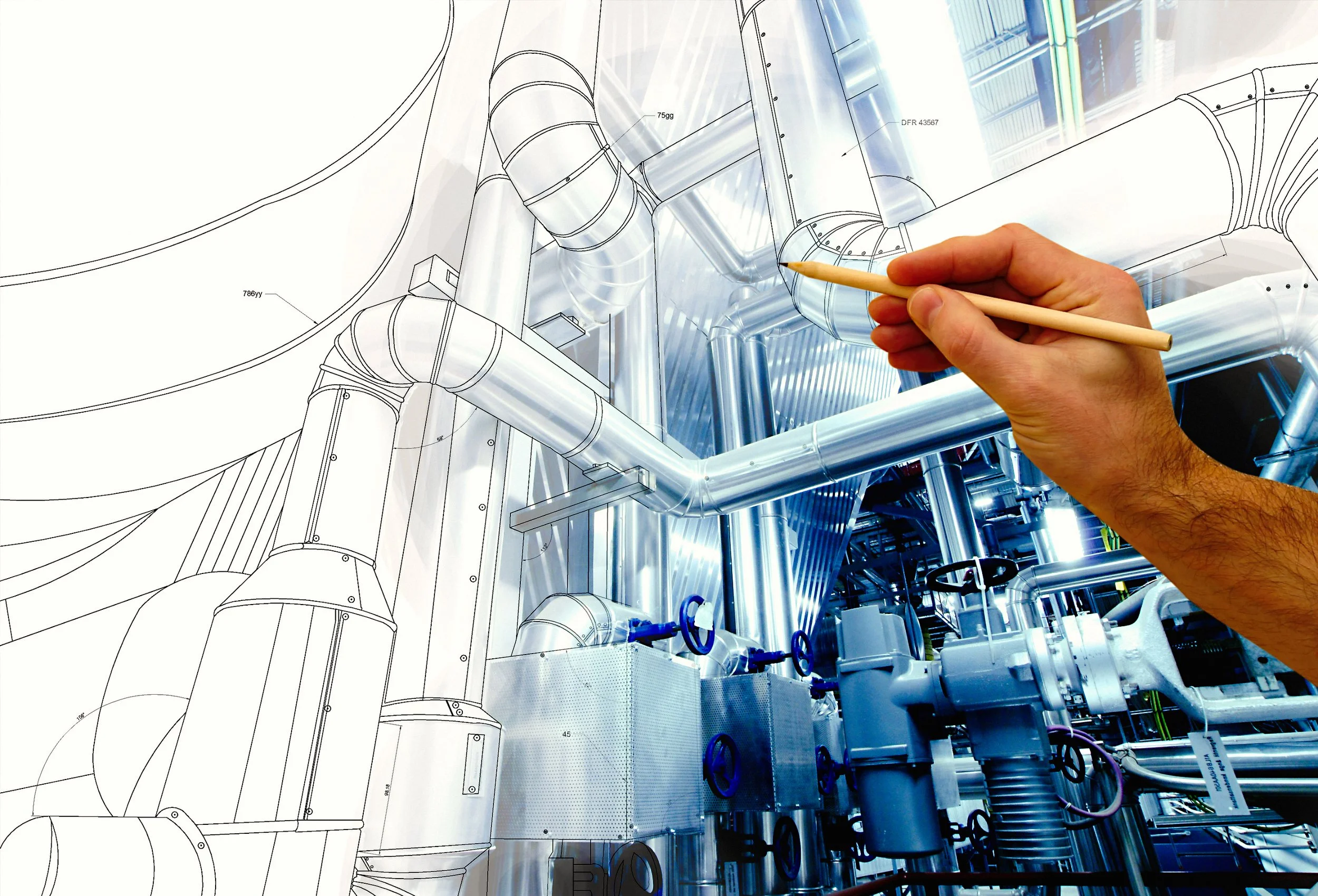

A Trusted Partner for Your

Hardest Problems

At Refined Engineering, we bring decades of combined engineering experience to solve the hardest mechanical engineering challenges in the fixed pressure equipment space. We excel in providing expert consulting engineering services throughout the equipment lifecycle from developing conceptual details to performing retirement assessments. Trust our experienced professionals to deliver precise insights and effective solutions for whatever issues come your way.

In engineering, good enough isn't good enough.

We refine until it's right.

Industries Served

-

Refining

-

Equipment Manufacturers

-

Petrochemical/Chemical

-

Midstream

-

Renewable Fuels

-

Power Generation

Our Services

-

Conceptual engineering support (FEL/FEED)

Quotation calculations

Owner’s Engineer services

Conceptual and detailed equipment drawing creation

Mechanical purchasing specifications

RFQ and bid tab reviews

Manufacturing facility audits

-

Detailed ASME/API design calculations for pressure vessels, heat exchangers, piping, and tanks

Design by analysis per ASME Section VIII, Division 2 Part 5 / Advanced analysis (FEA) services

Design certification by a Professional Engineer

Associated calculations:

Lifting

Shipping

PWHT (Post Weld Heat Treatment)

Pipe support

Platforms

ASME code case/interpretation champion

-

Rerate/alteration calculations

Repair plan drawings and calculations

Certification of rerate/alteration/repair by a Professional Engineer

API 510 documentation and nameplate supply

-

Level 1, 2, and 3 Fitness-for-Service evaluations for:

Brittle fracture

Metal loss (general, local, & pitting)

Hydrogen damage (Blisters, HIC, SOHIC)

Misalignment/Distortion

Creep

Fire damage

Dents/Gouges

Laminations

Fatigue

-

Minimally documented equipment evaluations

Suitability for service assessments

Bolted joint troubleshooting

PWHT sizing and buckling assessments

Failure analysis

Variance or state special applications for non-documented or incorrectly stamped equipment

-

Site staffing augmentation

Turnaround support and staffing

Emergency response

Owner’s engineer/third party reviewer