Front End Engineering and Conceptual Design

-

Build the right scope before you build anything. Refined Engineering establishes a clear, defensible basis for your project—aligning scope, cost, schedule, and risk—so detailed design and procurement move fast and with confidence.

Typical deliverables

Basis of Design (BoD) with assumptions, limits, and success criteria

Concept layouts and tie-in plans; constructability and turnaround constraints

Early BFDs/PFDs and preliminary equipment lists & datasheets

First-pass sizing for pressure vessels, exchangers, and critical piping

Codes & standards map (e.g., ASME VIII/B31.3, API) and initial materials screening

Budgetary vendor quotes and Class 4/5 cost & schedule ranges

Risk register and phased execution plan (Pre-FEED/FEED handoff)

Decision-ready outcomes

Clear scope definition and viable alternatives

Fewer changes, fewer surprises, better bids

Early stakeholder alignment and permit readiness

-

Your independent technical advocate—from concept to startup. Refined Engineering safeguards your objectives, keeps EPCs and vendors aligned, and assures code-compliant, operable, and maintainable outcomes.

Typical services

Scope & requirements stewardship: BoD validation, performance criteria, stage-gate readiness

Procurement support: mechanical specs, vendor lists, RFQs, bid tabs, TQs, and negotiations

Design assurance: PFD/P&ID reviews, datasheet checks, spot-verification of calcs, materials/corrosion selection, ASME/API compliance

Constructability & operations: layout and tie-in planning, turnaround constraints, access, lifting, and modularization reviews

Vendor management: document/submittal reviews, ITPs, FAT/SAT witnessing, NCR resolution

Project governance: risk/change control, schedule & cost realism checks, value engineering, decision logs, and weekly reporting

Field & quality oversight: site walks, QA/QC audits, WPS/PQR review, hydrotest packages, punchlists

Commissioning & handover: pre-startup reviews, procedures, critical spares, O&M manuals, turnover dossiers

Owner-ready outcomes

Design, budget, and safety objectives kept in lockstep

Fewer change orders and claims; stronger contractual leverage

Faster submittal cycles and cleaner, traceable turnover packages

Documented compliance with ASME VIII/B31.3 and relevant API standards

-

Get apples-to-apples, code-compliant bids—and equipment that installs and operates the way you expect. Refined Engineering prepares complete mechanical purchasing specifications for vessels, exchangers, columns, reactors, and related refinery pressure equipment.

What we include

Spec package: Mechanical Requisition (MR), datasheets, scope boundaries, battery limits, and responsibilities matrix

Design basis: MAWP/MDMT, duty cases, corrosion/erosion allowances, design life, sour-service requirements (e.g., NACE MR0175/ISO 15156)

Codes & standards: ASME Section VIII Div. 1/2, B31.3 interfaces, and applicable API/ASME/MSS references—by edition

Mechanical details: nozzle schedule & ratings (ASME B16.5/B16.47), internals, supports/lugs, platforms/ladders, insulation/jacketing allowances, nameplate/stamping (U/U2 as applicable)

Materials & fabrication: metallurgy, impact testing, hardness limits, cladding/overlay, WPS/PQR, PWHT requirements

Inspection & testing: ITP with hold/witness points, NDE scope (RT/UT/MT/PT), hydro/leak tests, PMI, documentation for MDR

Coatings & preservation: surface prep standards, coating/lining systems, preservation/packaging for shipment and laydown

Vendor data & schedule: VDRL/VDSL, drawing/calculation requirements, GA & nozzle orientation drawings, plate maps, document transmittal cadence

Bid alignment: technical bid forms, deviation list templates, and evaluation criteria to speed TBE and award

Procurement-ready outcomes

Comparable bids with fewer RFIs and cleaner contracts

Assured ASME/API compliance and lower lifecycle risk

Faster approvals, smoother fabrication, and traceable turnover packages

-

Select the right fabricator before steel is cut. Refined Engineering performs rigorous shop audits and structured vendor evaluations to de-risk quality, schedule, and cost for refinery pressure equipment.

What we evaluate (on-site & desk)

ASME authorization and compliance: active U/U2 stamps, National Board registration, Authorized Inspector engagement, code edition control

Welding & heat treatment: WPS/PQR/WPQ, consumable control, PWHT furnaces (TUS/SAT), hardness/impact testing, overlay/cladding capability

NDE capability: RT, UT/PAUT, MT/PT, PMI, hydro/leak testing facilities and procedures

Fabrication capacity & constraints: plate rolling/forming limits, machining, lifting/rigging, coating/lining booths, shop loading and throughput

HSE & workforce: safety performance, training, supervision ratios, subcontractor control

Performance data: on-time delivery, change frequency, punchlist/NCR rates, recent client references

Audit deliverables

Pre-audit desk review and risk profile

Detailed audit checklist with photos and objective findings (major/minor/observations)

Corrective Action Requests with due dates and verification plan

Go/hold recommendations tailored to your scope, schedule, and risk tolerance

Approved bid list—scoring & upkeep

Weighted scorecards across capability, capacity, QA/HSE, schedule reliability, geography/logistics, and financial stability

Bid eligibility tiers (preferred / conditional / probationary) with clear entry and exit criteria

Ongoing surveillance: periodic mini-audits and KPI tracking to keep the list current

Owner-ready outcomes

Fewer fabrication surprises and cleaner MDRs

Comparable, credible bids from qualified shops

Higher on-time delivery and first-pass acceptance at FAT/SAT

Documented due diligence for internal and regulatory audits

Sample Projects

-

Pilot Plant Equipment Design

1. Main Problem Identified: Full system design for a high-temperature, specialty production pilot plant.

2. Approach: Created multi-system design basis documentation covering reactor, tanks, piping, and auxiliary vessels using ASME Section VIII concepts where applicable.

3. End Results: Design package delivered with detailed vessel specs, safety margins, and equipment integration strategy for all pressure equipment. Readied for vendor fabrication

-

Pressure Vessel Shop Audit

1. Main Problem Identified: Concerns regarding a fabrication company’s capabilities to manufacture a nickel alloy (Alloy 625) vessel with sufficient quality and schedule control.

2. Approach: Performed two-day onsite fabrication shop audit. The evaluation included interviews with staff, walk-through of fabrication facilities, review of procedures, equipment, project tracking systems, inspection of alloy handling, welding practices, engineering team qualifications, subcontracting dependencies, and contamination control practices.

3. End Results: The fabricator was deemed limited but competent with consistent quality in core capabilities. No red flags were found that would necessitate removing the vessel from the company’s scope. Confirmed confidence in fabricator’s ability to fabricate the vessel. Recommendations provided: Implement protective handling protocols for Alloy 625. Engage a qualified Welding Engineer to review new weld procedures Require a formal Inspection and Test Plan (ITP) to control fabrication hold points

-

Evaluation Of Design Codes

1. Main Problem Identified: Uncertainty around potential benefits of using ASME Section VIII, Division 2 for new vaporizer exchanger design

2. Approach: Compared minimum thicknesses and maximum allowable pressures across all major components using COMPRESS software; applied MA46 to isolate impacts of design margins vs. equation conservatism.

3. End Results: Found minor efficiency gains (~8–10%) in wall thickness and allowable pressure for external pressure components; recommended continued use of Division 1 due to minimal savings, higher fabrication costs, and tighter tolerances required under Division 2.

-

Purchasing Spec Creation

1. Main Problem Identified: An in-service reactor vessel had widespread internal erosion, driving remaining wall below site minimums and making repair uneconomical ahead of a planned turnaround. A replacement was required, but prior procurements suffered from inconsistent vendor assumptions that led to change orders, nozzle misalignment, and schedule risk.

2. Approach: A comprehensive Mechanical Purchasing Specification (M-Spec) was authored to define design and construction requirements per ASME Section VIII, Division 1 with supplementary analysis where nozzle external loads warranted, including MAWP/MDMT, corrosion allowance, materials, impact testing, NDE, PWHT, coatings, and nameplate/U-stamp requirements. The deliverables included purchasing and bid requirements (schedule, pricing breakdown, exceptions register), a process/mechanical datasheet, conceptual GA drawings with nozzle map and allowable external loads, and a vendor data/ITP matrix with hold points, MDR content, shipping/lifting instructions, and preservation criteria.

3. End Results: The standardized package yielded three fully compliant “apples-to-apples” bids with fewer than five minor exceptions, eliminating scope ambiguity across vendors. The selected fabricator committed to an acceptable turnaround cycle and a cost reduction versus the last comparable buy, and IFC vendor drawings matched existing foundations and centerlines with minimal RFIs during installation. The new vessel entered service with leak-free performance and documentation complete for turnover.

-

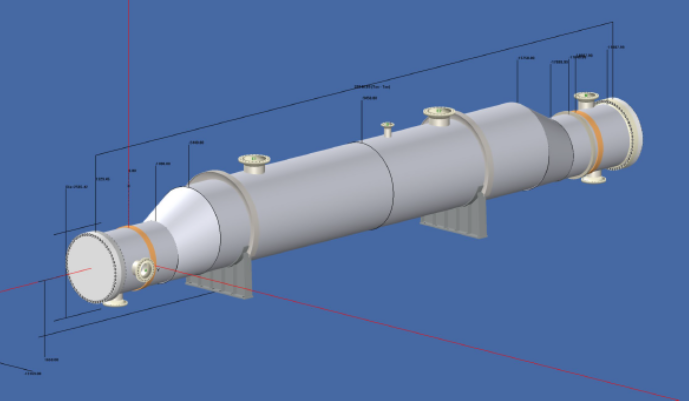

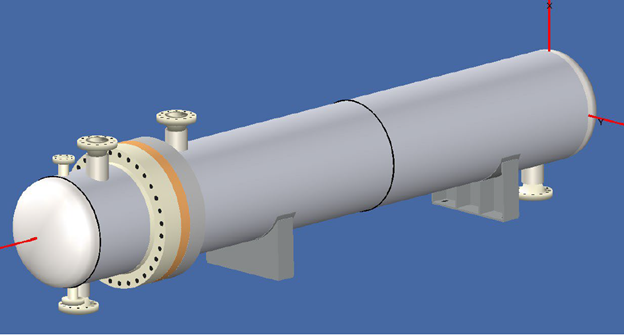

Design of Replacement Heat Exchanger

1. Main Problem Identified: Need to increase design pressure on the tube side of six identical, new exchangers beyond original design of old equipment.

2. Approach: Performed ASME Section VIII, Division 1 assessment using COMPRESS software. Completed review of shell and tube side MAWP and required thickness calculations. Tubesheet and nozzle re-evaluation was necessary for higher pressures.

3. End Results: Tube side successfully redesigned for increased design conditions on replacement exchangers. Only minor physical modifications required; gasket and bolt configuration was maintained. Supports operational flexibility with increased throughput.