Project and Turnaround Support

-

Close critical gaps with seasoned engineers who slot into your processes on day one. Refined Engineering provides on-site (or hybrid) support to surge for turnarounds, projects, and reliability—while maintaining code alignment and documentation discipline.

What we provide

Mechanical/static, project, and reliability engineers embedded with your team

Turnaround/outage coverage (days/nights), shift flexibility, and rapid mobilization

Safety-ready personnel (site orientation, TWIC/backgrounds as required); PPE and tooling standards

Optional PE oversight/responsible charge available where scope requires

Typical roles we fill

Mechanical/Static: pressure equipment, piping, and tank engineering (ASME VIII/B31.3, API 650/620)

Owner’s Engineer: vendor coordination, submittal/TQ management, bid tabs, and shop/factory visits

Project/TA Engineering: scope development, estimates, planning, ITPs, field engineering and walkdowns

Reliability/MI: API 510/570/653 interfaces, bad actor elimination, corrosion circuit coordination

How we integrate

Kickoff alignment on scope, procedures, and KPIs; clear RASCI with your stakeholders

Plug-in to your tools (SAP/Maximo, document control, CMMS, MOC, DMS/CAD)

Weekly cadence: risk/issue log, look-ahead, and decision register; transparent change control

Typical tasks

Field engineering, redlines, and RFI resolution; vendor drawing/calculation reviews

Turnaround workpacks, lift/rigging checks, tie-in planning, punchlists, and test packages

Budget/schedule realism checks, progress reporting, and closeout documentation

Light calculations and screening checks on site; deeper analyses routed through our office as needed

Deliverables

Weekly status reports and KPI dashboard; risk/decision logs and action trackers

Approved workpacks, marked drawings, and turnover dossiers (MDR-ready)

Closeout summary with lessons learned and backlog/deferral recommendations

Owner-ready outcomes

Immediate capacity to hit milestones and de-risk outages

Fewer RFIs and smoother handoffs between field, vendors, and design teams

Consistent, auditable documentation that stands up to client and regulatory review

-

Hit scope, hit schedule, and start up clean. Refined Engineering embeds with your team to plan, execute, and close out outages—keeping safety, code compliance, and documentation front and center.

Before the outage (plan & prepare)

Scope definition and freeze; risk register and critical path review

Workpacks: isolation plans/blind lists, tie-in details, lift/rigging checks, hydro/leak test boundaries, ITPs, and QA hold points

Vendor readiness: bid tabs, submittal reviews, spare/kit verification, shop visits/FAT alignment

Materials & calcs: t_min checks, rerate screens, flange torque/tension tables (PCC-1), temporary support/stability notes

Procedures: demob/removal/installation sequences, PWHT plans (WRC 452), PSV handling/testing coordination

During the outage (field execution)

On-site field engineering and redlines; RFI triage and rapid calc checks

Daily walkdowns, punchlist management, NCR/CAPA closure, and weld/NDE oversight

Exchanger/column internal fit checks, nozzle load/alignments, piping support adjustments

Turnaround control room support: progress KPIs, decision log, emergent-work scoping with schedule/cost impacts

Startup & turnover (finish strong)

Pressure/leak tests, reinstatement, and flange management verification

PSV reinstatement, setpoint confirmations, and relief documentation updates

PSSR/commissioning support, operating envelope confirmation (pressure/temp/ramp)

Turnover dossiers: MDR, updated P&IDs/isos, datasheets, and as-built sketches

Deliverables

Approved workpacks and field checklists; torque/tension tables and test procedures

Daily status reports with risks, constraints, and mitigation actions

PE-reviewed notes/calcs where required; organized turnover package ready for audit

Owner-ready outcomes

Safer execution with fewer RFIs and rework

Schedule discipline through clear engineering decisions on the critical path

Clean startup and traceable documentation that satisfies clients, insurers, and regulators

-

When the unexpected happens, you need fast, defensible engineering. Refined Engineering mobilizes quickly—remotely or on-site—to stabilize conditions, protect people and assets, and chart the shortest safe route to recovery.

When to call us

Leaks/ruptures, overpressure/vacuum events, exchanger or column upsets

Fire/heat exposure, impacts/dropped objects, storm or freeze damage, power trips

Startup/shutdown excursions, relief device anomalies, flange/joint failures

What we do (immediately)

Incident triage with ops/ICS: isolate, depressure/vent, establish safe envelopes

Make-safe checks: temporary supports/shoring, hot/cold work limits, leak-mitigation options

Rapid engineering screens: MAWP/MDMT sanity, external pressure/vacuum risk, flange torque/tension (PCC-1), nozzle/load checks

Relief/device review: setpoints, blocked-in/thermal cases, temporary protection strategies

Evidence plan for later RCA (without slowing recovery)

Stabilize & recover (next 24–72 hours)

Focused FFS screening (API 579 Level-1/targeted Level-2) for metal loss, distortion, dents/gouges, brittle fracture, hydrogen or fire damage

Hot-spot/temporary derate envelopes (pressure/temperature/ramp) and monitored operations plans

Vendor & contractor coordination: temporary repair concepts, test boundaries, ITP/hold points

Regulator/insurer support and clear communications for leadership and the field

How we work

Integrate with your Incident Command/System of record; maintain a decision log and RFI tracker

PE oversight available; stamped emergency engineering notes where jurisdictionally required

Escalate to advanced analysis (VIII-2 Part 5/FEA) only when it changes a critical decision

Deliverables

Emergency Engineering Memo: hazards, limits, and required controls (owner-approved)

Temporary operating envelope (pressure/temp/vacuum), flange/joint settings, and test procedures

Field sketches/redlines, checklists, and turnback criteria for restart

Daily status summaries; close-out package with actions, assumptions, and MDR updates

Owner-ready outcomes

Faster, safer stabilization with fewer secondary incidents

Clear, auditable basis for decisions under ASME/API and site procedures

Shorter time to a clean restart—and better inputs for subsequent root-cause analysis

-

Your independent technical advocate—from concept to startup. Refined Engineering safeguards scope, cost, and safety, keeping EPCs and vendors aligned while assuring code-compliant, operable, and maintainable outcomes.

What we do

Scope & requirements: Basis of Design stewardship, stage-gate readiness, value engineering, and decision logs.

Procurement support: mechanical specs, vendor lists, RFQs, bid tabs, TQs/deviation control, and negotiations.

Design assurance: PFD/P&ID and layout reviews, datasheet checks, spot-verification of calcs, materials/corrosion selection, ASME/API/OSHA compliance.

Fabrication quality: VDRL/VDSL management, ITPs and hold points, shop audits, FAT/SAT witnessing, NCR/CAPA closure.

Constructability & operations: tie-in planning, access/lifting, turnaround constraints, modularization, and maintainability checks.

Risk & governance: schedule/cost realism, change management, interface control, and weekly KPI reporting.

Field & commissioning: site engineering support, punchlists, test packages, PSSR, procedures, spares, and clean turnover dossiers (MDR).

How we work

Single-point technical leadership with PE oversight as required

Transparent RFI/TQ tracking, revision control, and audit-ready documentation

Alignment with your systems (CMMS/DMS/MOC) and safety processes

Deliverables

Comment/resolution logs and approval matrices

PE-reviewed design notes, calculation spot-checks, and compliance letters

Bid evaluations, shop/field visit reports, ITPs/FAT records, and turnover packages

Owner-ready outcomes

Fewer change orders and claims; stronger contractual leverage

Designs that start up clean—code-compliant and maintainable

Clear visibility to scope, risks, and progress from day one

Sample Projects

-

Reliability Engineering Staff Support

1. Main Problem Identified: The refinery faced a short-term staffing gap from turnover and parental leave, leading to rising bad-actor recurrences, RCFA slippage, and PM compliance falling to 82%. A near-term turnaround and higher crude variability amplified the risk of repeat failures, increased maintenance cost, and lost barrels.

2. Approach: An embedded reliability engineer stabilized daily reliability workflows while building durable systems—standing up a weekly defect-elimination cadence, executing bad-actor reviews and RCFA (Apollo/5-Whys) on the top 20 events, and refreshing criticality rankings to refocus on assets. The workstream cleaned data and job plans, rationalized spares, optimized PM/CBM, and deployed KPI dashboards with a maintenance–operations governance rhythm.

3. End Results: In six months, PM compliance recovered to 96%, repeat failures on the top five bad actors dropped, and the >90-day corrective backlog fell, avoiding ~1,250 hours of unplanned downtime and ~$1.8MM in estimated loss-to-plant. The engagement delivered a hardened reliability playbook (standards, job plan library, RCFA templates, and a risk register) and trained two staff engineers to sustain gains after handover.

-

Turnaround Engineering Support

1. Main Problem Identified: A refinery unit faced a compressed 28-day outage with an overloaded worklist—column tray repairs, heater convection coil replacement, two new tie-ins, and more than 500 controlled flange breaks—creating high risk to the critical path and a leak-free startup. Historic delays were tied to late field RFIs, incomplete test packages, and inconsistent flange assembly practices that produced hot-start leaks.

2. Approach: A two-engineer on-site team provided 24/7 field engineering and QA/QC, owning RFI triage, weld mapping, and mechanical-integrity hold points while running daily SIMOPS and critical-path reviews with construction and operations. We built and issued pressure-test packages, executed controlled flange management per PCC-1 (torque/tension tables, gasket QA), coordinated NDE (MT/PT/UT/PAUT) and PWHT, and closed discovery work via rapid calcs and red-lined drawings for approval. Pre-startup, we led line walks and reinstatement (blind lists, LOTO clearance, torque verification, hydro/pneumatic tests) and delivered as-built P&IDs and turnover dossiers.

3. End Results: The unit achieved mechanical complete on day 26 and met the day-28 window, with zero recordable incidents and a leak-free startup across 100+ flange breaks. Critical-path tasks (heater coil swap and tower tray repairs) finished with at least 18 hours of float, and discovery work—19 additional welds and two nozzle repads—was absorbed without schedule slip or capital variance. The engagement delivered a reusable flange-management toolkit and updated test-package templates, reducing next-outage planning time and setting a standard for future turnarounds.

-

Emergency Repair Plan Development and Certification

1. Main Problem Identified: High-pressure low-temperature separator built to ASME Section VIII, Division 2 required a repair plan and certification by a licensed professional engineer to ensure compliance with NBIC and ASME Section VIII-2.

2. Approach: Reviewed User’s Design Specification (UDS), Manufacturer’s Data Report (MDR), PWHT procedures, weld overlays, and insulation installation methods in accordance with NBIC NB-23 Part 3 rules. Developed the details of the repair plan in conjunction with client specifications and requirements.

3. End Results: The PE certified repair plan was provided to the client as complete and code-compliant; approved for implementation under National Board Inspection Code guidelines. Repairs were completed and the vessel was put back into service successfully.

-

Purchasing Specification Creation

1. Main Problem Identified: An in-service reactor vessel had widespread internal erosion, driving remaining wall below site minimums and making repair uneconomical ahead of a planned turnaround. A replacement was required, but prior procurements suffered from inconsistent vendor assumptions that led to change orders, nozzle misalignment, and schedule risk.

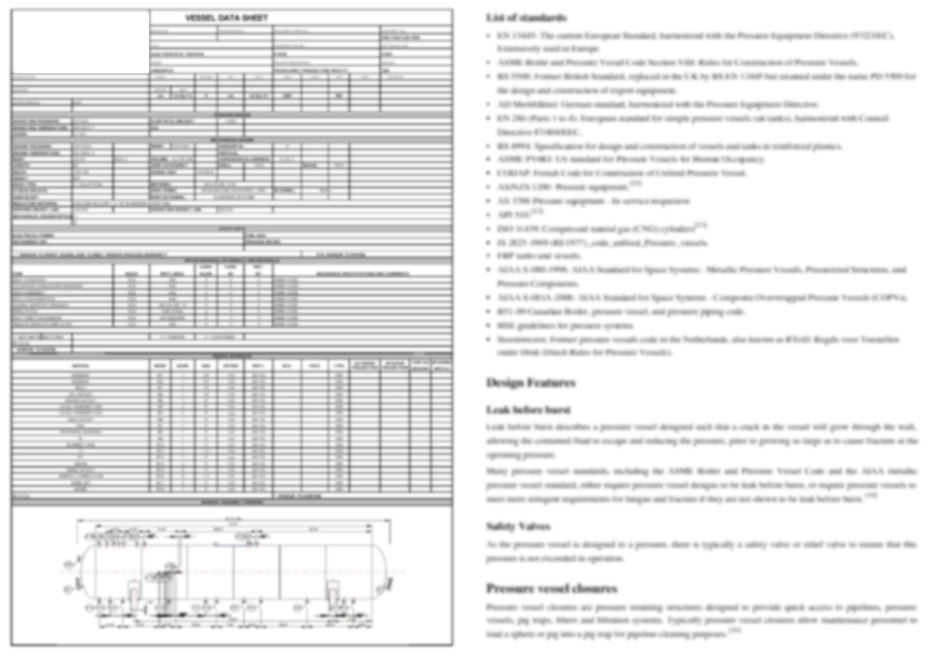

2. Approach: A comprehensive Mechanical Purchasing Specification (M-Spec) was authored to define design and construction requirements per ASME Section VIII, Division 1 with supplementary analysis where nozzle external loads warranted, including MAWP/MDMT, corrosion allowance, materials, impact testing, NDE, PWHT, coatings, and nameplate/U-stamp requirements. The deliverables included purchasing and bid requirements (schedule, pricing breakdown, exceptions register), a process/mechanical datasheet, conceptual GA drawings with nozzle map and allowable external loads, and a vendor data/ITP matrix with hold points, MDR content, shipping/lifting instructions, and preservation criteria.

3. End Results: The standardized package yielded three fully compliant “apples-to-apples” bids with fewer than five minor exceptions, eliminating scope ambiguity across vendors. The selected fabricator committed to an acceptable turnaround cycle and a cost reduction versus the last comparable buy, and IFC vendor drawings matched existing foundations and centerlines with minimal RFIs during installation. The new vessel entered service with leak-free performance and documentation complete for turnover.

-

Emergency FFS to Restart Unit

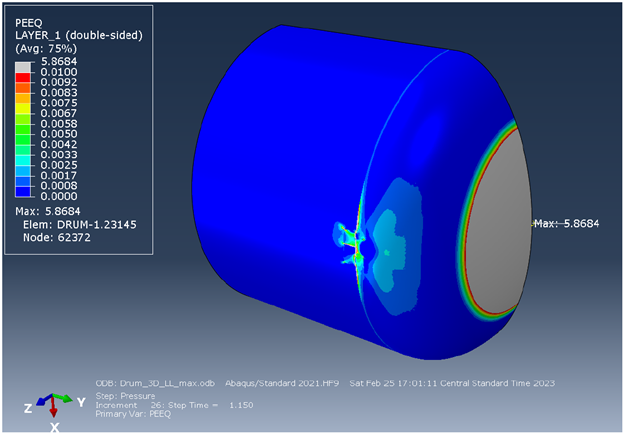

1. Main Problem Identified: Inspection found crack-like indications on the outer shell near the head-to-shell weld of a recycle-service vessel; attempts to grind out the defects were unsuccessful, leaving several small flaws within locally thinned cavities. The evidence pointed to stress corrosion cracking driven by chlorides in insulation or fluoride exposure, and the weld discontinuity at the head junction meant a higher-rigor assessment was warranted.

2. Approach: A Level 3 fitness-for-service evaluation per API 579/ASME FFS-1 was performed, modeling the local thinned areas with a nonlinear limit-load analysis and developing a through-wall stress profile for crack assessment. Crack stability was checked using Part 9 Failure Assessment Diagram methods with conservative assumptions (infinite-length surface crack at measured depth, residual weld stresses), while Part 5 addressed the LTAs under design pressure loading with appropriate symmetry constraints.

3. End Results: Both the LTA and crack assessments were acceptable for continued service: the limit-load model showed margin and the crack assessment points plotted below the FAD acceptance curve. To manage the SCC mechanism and risk, recommendations included applying a removable external barrier, initiating close post-startup monitoring (about monthly initially), and recognizing that with 316SS toughness any progression would likely present as leakage rather than catastrophic fracture; longer-term run/replace decisions were tied to risk tolerance.

-

Amine Stripper FFS during Turnaround

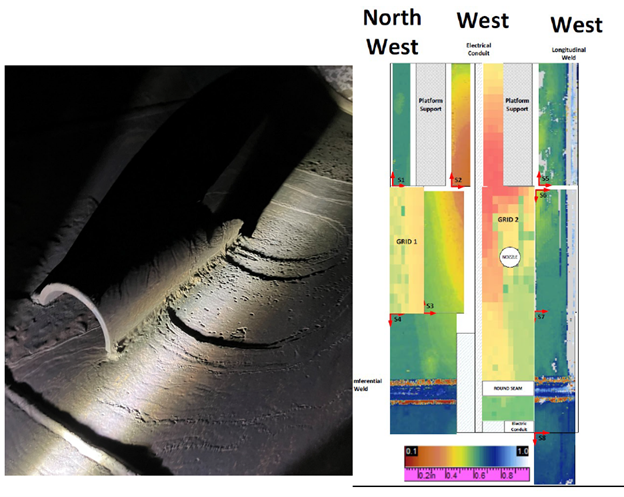

1. Main Problem Identified: Local thin areas were discovered on the second bottom shell course of an amine stripper vessel, prompting a fitness-for-service evaluation. The assessment considered the design condition and included site loads, while external pressure was excluded via administrative controls.

2. Approach: A Part 5 Level 3 assessment per API 579 used elastic-plastic analysis requiring convergence at an effective load factor of 3.6 for plastic-collapse acceptance; buckling was evaluated by ASME VIII-2 Method B using an eigenvalue-derived imperfection equal to 1% of vessel diameter with a stability target of ≥ 1.67. Global loads were calculated in COMPRESS and applied to a bottom-section FE model that incorporated measured thickness mapping and corrosion allowances. The load set included pressure thrust, deadweight, wind shear/bending, and platform clip loads.

3. End Results: The vessel satisfied the acceptance criteria—plastic-collapse cases and buckling analysis achieved acceptable load factors. The evaluation found the component acceptable with RSF = 0.9 and a 1/16-in future corrosion allowance at the LTA, recommended re-inspection in six months, and treated external pressure by administrative control rather than calculation.