Rerating, Repairs, and Alterations

-

Restore design margin and align nameplates with reality—without touching repairs. Refined Engineering delivers code-grounded rerate and alteration calculations for refinery vessels, exchangers, piping, and tanks to support safe, compliant, and efficient operation.

What we deliver

Rerate calculations: updated MAWP/MDMT and design conditions; minimum required thickness; joint efficiency and corrosion allowance updates; PSV/vent revalidation (API 520/521/2000).

Alteration calculations: added/upsized nozzles, internals/support changes, openings and reinforcements, external pressure, and wind/seismic impacts; drawing and nameplate updates.

Design basis confirmation: materials verification, load cases, brittle-fracture/MDMT checks, and edition control for applicable codes.

Data recovery for minimally documented equipment: thickness surveys, National Board/nameplate record checks, and reconstructed design inputs.

Codes & standards we align to

ASME VIII-1/2, ASME B31.3, API 650/620; NBIC (Alterations); API 510/570/653 for in-service documentation and rerating requirements.

Package contents

Sealed (where required) calculation reports with clear assumptions and acceptance criteria

Redlined/updated GAs, nozzle schedules, datasheets, and nameplate wording/stamping requirements

PSV/vent setpoint confirmations and device datasheet updates

Technical query/deviation list and turnover index (MDR)

Owner-ready outcomes

Defensible rerates and alterations that pass audits and jurisdictional review

Accurate setpoints and documents for operations and MI programs

Fewer RFIs/change cycles and faster approvals from inspectors and EPCs

-

Get damaged equipment back in service safely—with code-grounded engineering and build-ready instructions. Refined Engineering develops repair evaluations, calculations, and detailed repair plans for refinery vessels, exchangers, piping, and tanks.

What we evaluate

Degradation mechanisms: general/locally thin areas, pitting/grooving, distortion/misalignment, crack-like flaws, nozzle/repad damage, external pressure and cyclic concerns

Service conditions: updated pressures/temperatures, MDMT/brittle fracture checks, wind/seismic and temporary loads (lifting/shoring)

Remaining life and operability: acceptance against API 579 (Levels 1–3 as warranted), with targeted FEA support for complex details

Engineering & calculations

Sizing of sleeves, repads, insert plates, weld buildup/overlay, nozzle replacements/upsizes, local stiffeners/girders, and temporary attachments

Check of primary/secondary stresses, reinforcement areas, external pressure stability, and post-repair MAWP/MDMT and relief implications

Welding/PWHT requirements based on materials, thickness, and code exemptions

Repair plans (shop/field-ready)

Drawings and step-by-step method statements; fit-up tolerances and sequencing

WPS/PQR guidance, preheat/interpass/PWHT profiles, heat-input controls

ITP with hold/witness points; NDE scope (MT/PT/UT/RT/PMI); pressure/leak testing procedures

Isolation/vent/drain, access/lifting provisions, preservation/coating touch-up, and turnover docs (MDR updates)

Codes & standards we align to

API 579-1/ASME FFS-1, ASME PCC-2, NBIC Part 3 (Repairs & Alterations), API 510/570/653, ASME VIII-1/2, ASME B31.3

Deliverables

Sealed (where required) calculation report and acceptance summary

Repair drawings/details and bill of materials

ITP/NDE/test procedures and document transmittal index

AI/R-stamp coordination notes and nameplate/reporting requirements, where applicable

Owner-ready outcomes

Safe, auditable return-to-service with clear acceptance criteria

Fewer RFIs and faster field execution through unambiguous, buildable plans

Documented compliance for inspectors, insurers, and mechanical integrity programs

-

Keep vessels compliant and audit-ready. Refined Engineering prepares complete API 510 documentation—covering rerates, alterations, repairs, supplemental/new nameplates, minimally documented equipment evaluations, and owner/user rerate forms.

What we deliver

Rerate packages: updated MAWP/MDMT, conditions of service, PSV/vent setpoints, owner/user rerate forms, and nameplate wording.

Alteration & repair documentation: engineering basis, sketches/details, acceptance criteria, and coordination of NBIC R-1/R-2 forms with your R-Stamp organization and Authorized Inspector.

Nameplates: supplemental/replacement nameplate content, marking instructions, attachment method, and jurisdictional approvals as required.

Minimally documented equipment: data recovery (thickness surveys, materials verification, National Board/nameplate searches), reconstructed design basis, and new datasheets.

Program integration: updates to P&IDs/datasheets/asset registry, MOC inputs, and MI file structure for easy retrieval.

Codes & standards we align to

API 510 (Pressure Vessel Inspection Code)

NBIC Part 3 (Repairs & Alterations) and National Board registration practices

ASME Section VIII Div. 1/2 (design references) and API 520/521/2000 for relief consistency

Jurisdictional requirements (state/provincial submissions, where applicable)

Package contents

Sealed (where required) calculation report and engineering summary

Completed rerate/repair/alteration forms, deviation/TQ log, and transmittal index

Updated GAs, nozzle schedules, datasheets, and relief device documentation

Nameplate text and stamping/attachment instructions; MDR updates for turnover

Owner-ready outcomes

Clear, defensible compliance with API 510 and NBIC

Faster approvals and fewer NCRs during audits and inspections

Accurate asset records that align operations, inspection, and reliability programs

-

Independent, accountable engineering—sealed by a licensed PE. Refined Engineering provides certification services and serves in responsible charge for pressure equipment and piping projects, ensuring decisions are made by a qualified engineer with full technical authority and documentation control.

What we certify

Calculation packages (ASME VIII-1/2, B31.3, API 650/620, API 660/661) and relief device bases (API 520/521/2000)

Drawings and deliverables: GAs, nozzle orientation, supports/lugs, platforms/ladders, details and notes

Rerate/alteration design summaries, nameplate wording, and jurisdictional submittal documents

Letters of compliance/conformance tied to specific codes, editions, and project specifications

How we establish responsible charge

Defined scope of responsibility and approval matrix; design basis and assumptions log

Direct technical direction of work performed by our team and supervised collaborators

Formal review/closure of comments with traceable revision control and decision records

Coordination with Owner, fabricator, Authorized Inspector, and jurisdiction as required

Jurisdictional & sealing options

Digital or wet PE seals per state rules; multi-state coverage available subject to registration

Support for State Special/variance applications and permitting packages

Clear delineation of PE certification vs. manufacturer code stamping (U/U2/NB registration)

Deliverables

PE-signed/sealed reports, drawings, and certification letters

Transmittal index, edition control, and limitations/conditions of use

Audit-ready package for procurement, fabrication, and turnover (MDR)

Owner-ready outcomes

Defensible, code-grounded decisions under a licensed engineer’s responsibility

Faster approvals and fewer RFIs/change orders

Documentation that stands up to client, insurer, and regulatory review

Sample Projects

-

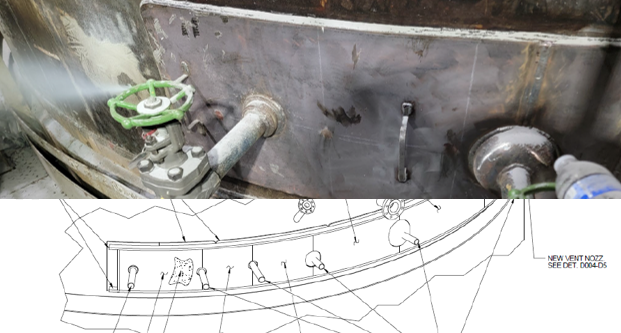

Heat Exchanger Shell Flush Insert Repair

1. Main Problem Identified: Degraded shell section near large inlet nozzle required structural repair while maintaining vessel integrity and code compliance.

2. Approach: Designed and specified a flush insert plate per API PCC-2 and NBIC Part 3 for ASME VIII-1 equipment; coordinated NDE, material certification, and weld procedure qualification per ASME IX.

3. End Results: Developed a complete field-executable repair plan with dimensional tolerances, WPS/PQR specs, 100% VT/PT/PAUT inspections, and NBIC R-1 form compliance; no hydrotest required due to validated PAUT results.

-

Shell Window Cutout and PWHT Evaluation

1. Main Problem Identified: Corrosion damage at lower shell courses of a tall tower required window cutouts to replace damaged shell sections and subsequent postweld heat treatment.

2. Approach: FEA-based assessment of column stability and shell deflection under wind and dead load during cutout and PWHT; evaluated per ASME VIII-2 and time dependent properties for creep buckling.

3. End Results: The window cutout segments met buckling and fit-up criteria with the material removed. Recommended full encirclement heating for thermal stress control. Confirmed structural stability without crane support during 360° PWHT at temperature.

-

Tank Roof Failure Investigation

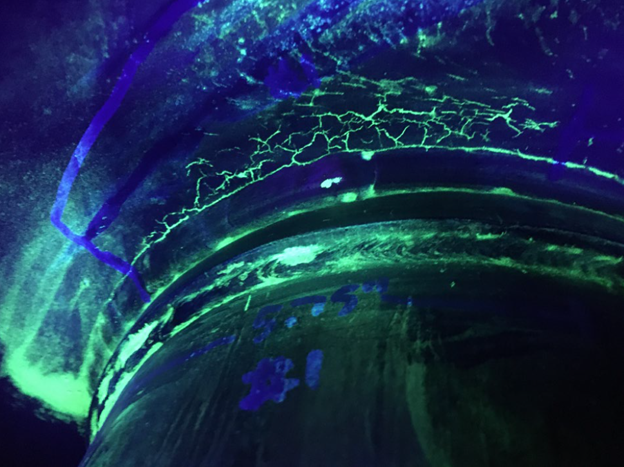

1. Main Problem Identified: The client experienced recurring cracking at the fermentation tank roof-to-stiffener fillet welds, concentrated near rafter-gusset “rat-hole” openings and persisting despite prior repairs that re-cracked in roughly two months..

2. Approach: Executed a four-phase root-cause investigation that included site visits to two of the client facilities, detailed field observations, and data review. The team verified API-650 and structural calculations, performed finite-element analysis using the ASME VIII-2 Structural Stress method, evaluated mixer-load effects and metallurgy/welding, and iteratively developed repair/redesign concepts.

3. End Results: The investigation concluded fatigue failure from pressure cycling as the root cause and showed the as-built configuration had an available fatigue life on the order of 50–60 days. Refined Engineerings’s recommended modifications increased predicted fatigue life to >50 years.

-

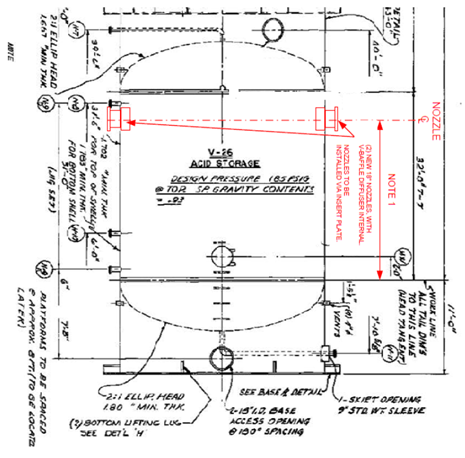

Vessel Alteration for Nozzle Installation

1. Main Problem Identified: Evaluate the design and installation of a new 18-inch nozzle with an insert plate at the top of an acid storage vessel. Mixed materials in the reinforcement zone and uncertainty that final piping loads could exceed preliminary values created risk of local overstress.

2. Approach: Performed alteration calculations per ASME and NBIC rules. Evaluated the nozzle and local insert plate’s capacity for piping loads using WRC Bulletin 537 and hand calculations.

3. End Results: Design met all ASME, NBIC, and client spacing/stress criteria, with high capacity for external piping loads. The configuration was fabricated, installed in the existing vessel, and successfully placed in service.

-

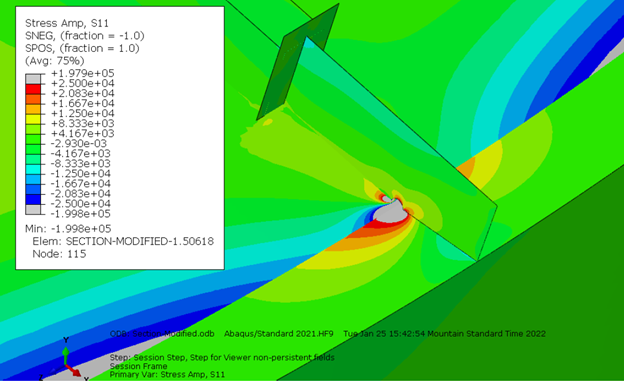

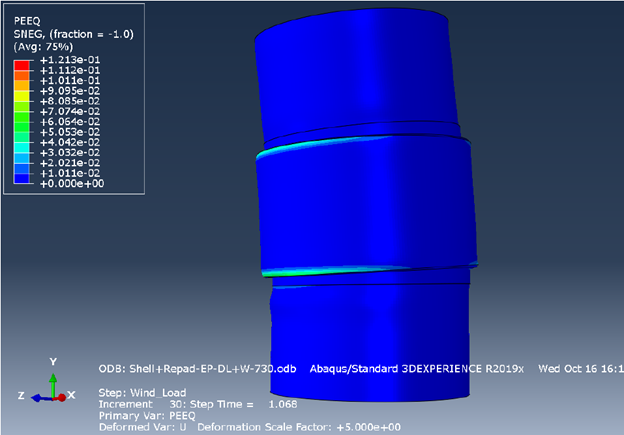

Incinerator Stack Enclosure

1. Main Problem Identified: Two large cracks were found on the incinerator stack; a full encasement box was proposed for repair.

2. Approach: Nonlinear elastic-plastic collapse and buckling evaluation using ASME VIII-2, Part 5, with ABAQUS FEA. Included wind and dead load modeling, heat transfer to determine metal temperature, and buckling analysis.

3. End Results: Leak box design confirmed structurally adequate with margin for collapse and buckling for all load cases with wind and dead load combined. Design approved for installation.

-

API 510 Rerate and Nameplate

1. Main Problem Identified: The drum was originally designed for −6 psig vacuum pressure, but certain operating scenarios could impose up to −13 psig external pressure. A formal assessment was needed to determine whether the external design pressure could be increased to −13 psig at the same temperature.

2. Approach: The vessel was modeled in COMPRESS and evaluated using ASME Section VIII, Division 2 rules via Mandatory Appendix 46 for a Division 1 vessel. Component MAWP-External checks showed the cylindrical shell governed, and acceptability was confirmed at the target external pressure.

3. End Results: From the assessment results, rerate forms per API 510 and a new nameplate were created to document the increased vacuum condition. The nameplate was affixed next to the existing ASME nameplate to complete the rerate process.

-

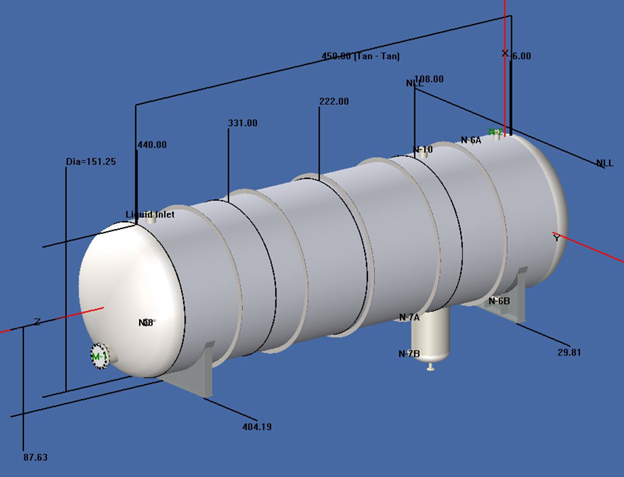

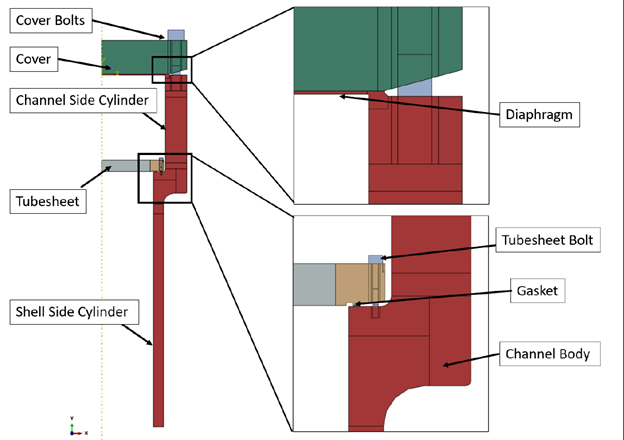

High Pressure Exchanger Rerate

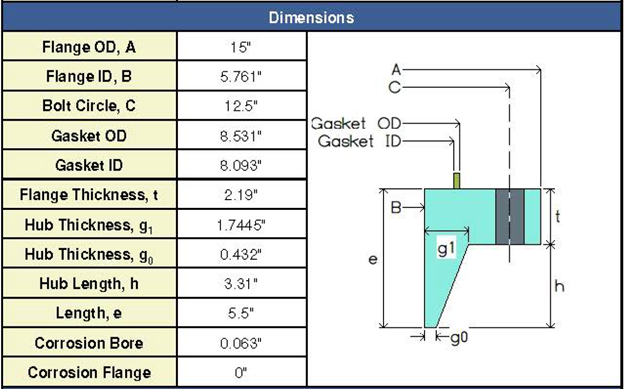

1. Main Problem Identified: The site needed to determine if two high pressure heat exchangers could be rerated to higher pressures without full replacement. Key constraints included existing Class 1500 flanges that do not meet the required pressure–temperature rating.

2. Approach: The exchangers were re-evaluated to the original code of construction using design-by-rule calculations in COMPRESS per ASME Section VIII-1 and TEMA for tubesheets, complemented by design-by-analysis (FEA) per Section VIII-2 for the channel body..

3. End Results: The rerate was feasible provided the Class 1500 flanges are replaced with new flanges meeting current ASME B16.5 ratings; tubesheet and channel cover thicknesses were adequate. A new hydrotest was required after the replacement of the flange. However, given the age/vintage of the existing steel and process conditions, additional evaluation to check for hydrogen damage was required for the hydrotest condition.

-

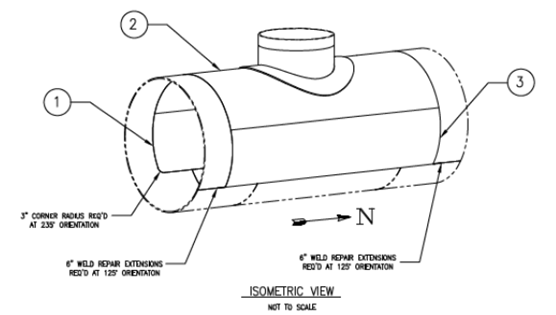

Leak Box Repair

1. Main Problem Identified: Aggressive shell erosion and through-wall failures near the old air grid of a FCC Regenerator. Erosion and through wall failures continued despite prior lap patch repairs.

2. Approach: Develop basic leak box design per ASME PCC-2 to enclose the existing lap patch repairs. Performed elastic-plastic FEA using ABAQUS to evaluate structural load capacity of the box in the event that the existing shell metal underneath the enclosure box was completely erroded away.

3. End Results: Verified performance of a refractory-lined leak box design to resist erosion while under pressure, temperature, and dead loads. The leak box successfully eliminate further leaks until the planned turnaround was reached months later.

-

Nozzle Cracking Assessment and Repair

1. Main Problem Identified: Cracking discovered at the weld between the inlet nozzle and shell of a stainless steel deaerator. Similar defects had been discovered at similar locations on other deaerators for the client.

2. Approach: Working with a metallurgical lab, destructive testing was performed to confirm the damage mechanism of the crack. Reviewed existing operating procedures and the physical characteristics of the inlet nozzle as well.

3. End Results: The damage mechanism was determined to be Caustic SCC from a combination of a poorly designed pH control system and non-standard hopper design. Redesigned the nozzle-hopper configuration to lower over-constraint and upgraded the local metallurgy since the pH control system was not readily modified.

-

Repair Plan Certification

1. Main Problem Identified: High-pressure low-temperature separator built to ASME Section VIII, Division 2 required a repair plan and certification by a licensed professional engineer to ensure compliance with NBIC and ASME Section VIII-2.

2. Approach: Reviewed User’s Design Specification (UDS), Manufacturer’s Data Report (MDR), PWHT procedures, weld overlays, and insulation installation methods in accordance with NBIC NB-23 Part 3 rules. Developed the details of the repair plan in conjunction with client specifications and requirements.

3. End Results: The PE certified repair plan was provided to the client as complete and code-compliant; approved for implementation under National Board Inspection Code guidelines. Repairs were completed and the vessel was put back into service successfully.

-

Piping Rerate

1. Main Problem Identified: Piping system operating at pressures exceeding original design; reevaluation needed to avoid costly flange replacements.

2. Approach: Performed ASME B31.3 and Section VIII Appendix 2 evaluation using COMPRESS software. MAWP determination for each flange under updated operating conditions. Corrosion allowance and pipe schedule reviews for compliance.

3. End Results: Most flanges acceptable for the increased operating pressure. One flange size limited to reduced corrosion allowance for compliance. Avoided widespread replacement while maintaining code compliance.

-

Tank Vacuum Rerate

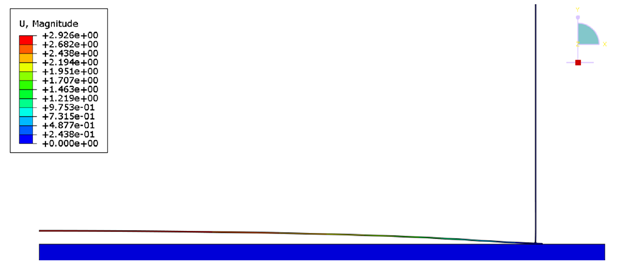

1. Main Problem Identified: Rerating of storage tank required for elevated vacuum pressure without internal liquid, which could otherwise result in tank bottom uplift or overstressing.

2. Approach: Nonlinear elastic-plastic FEA using axisymmetric modeling in Abaqus, per API 650/653 and API-579-1/ASME FFS-1. Evaluated whether stress/strain or practical deflection limits were exceeded.

3. End Results: Tank bottom predicted to deflect upward by a few inches, but all stresses/strains remained within allowable limits. Operation at increased vacuum condition is acceptable without liquid present.